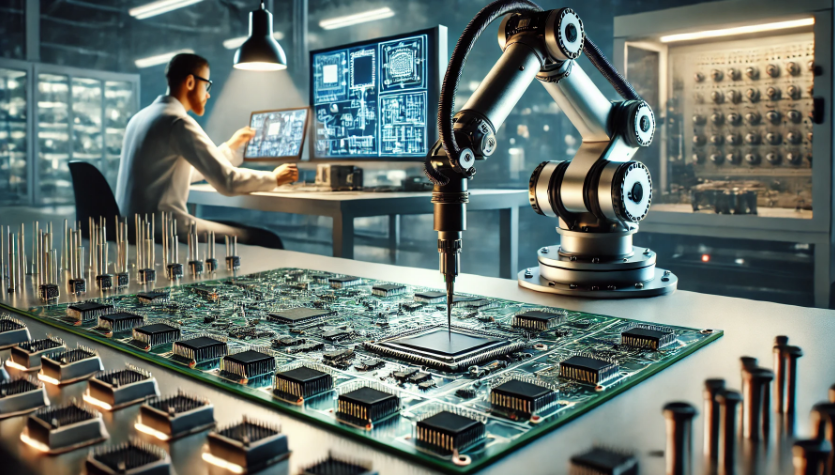

Circuit board assembly refers to the process of mounting and connecting electronic components to a printed circuit board (PCB). The resulting assembly becomes the heart of any electronic device, allowing it to perform its intended functions. The process can involve manual, semi-automated, or fully automated methods depending on the complexity and volume of the production.

Steps in Circuit Board Assembly

1. PCB Design and Preparation:

The process begins with designing the PCB layout and manufacturing the bare board. The board is typically made of a non-conductive substrate with copper traces to create the circuit pathways.

2. Component Procurement:

High-quality components are sourced, including resistors, capacitors, integrated circuits, and connectors. Reliable sourcing ensures the longevity and performance of the assembled circuit board.

3. Solder Paste Application:

Solder paste is applied to the PCB’s surface at the designated areas where components will be placed. This step is crucial for securing components to the board.

4. Component Placement:

Components are placed onto the board either manually or through automated machines like pick-and-place systems, which ensure precision.

5. Reflow Soldering:

The board is heated in a reflow oven, melting the solder paste to form strong connections between components and the PCB.

Types of Circuit Board Assembly Techniques

1. Surface Mount Technology (SMT): Components are mounted directly onto the surface of the PCB. This method is ideal for compact and high-speed applications.

2. Through-Hole Technology (THT): Components have leads that are inserted into holes in the PCB and soldered. THT offers stronger mechanical bonds, making it suitable for applications requiring durability.

3. Mixed Technology: Combines both SMT and THT to cater to complex designs with varied component requirements.

Key Considerations When Choosing a Circuit Board Assembly Provider

1. Technical Expertise: Ensure the provider has experience with your specific industry and application needs.

2. Quality Assurance: Look for certifications like ISO 9001 and IPC standards compliance to guarantee quality.

3. Turnaround Time: Choose a provider with efficient processes and the ability to meet deadlines.

4. Cost Transparency: Clear and competitive pricing helps avoid hidden costs and ensures budget adherence.

5. After-Sales Support: Reliable technical support and repair services are crucial for long-term satisfaction.

Conclusion

Circuit board assembly is a critical process that drives the functionality and reliability of modern electronics. Whether you’re an entrepreneur developing a new gadget or a manufacturer scaling production, understanding the essentials of CBA can help you make informed decisions. By partnering with a trusted assembly provider, you can ensure high-quality results, cost efficiency, and timely delivery for your electronic projects.

Write a comment ...