Prototype PCB assembly is the process of creating a small batch of PCBs to test and validate a design before moving to mass production. It involves assembling components onto a PCB to check its functionality, design accuracy, and reliability. This step is crucial for detecting and rectifying potential issues in the early stages of product development.

Key Steps in Prototype PCB Assembly

Design and Schematic Creation: The process begins with designing the PCB layout and creating schematics using software like Altium Designer or Eagle.

Material Procurement: Components and materials required for assembly, such as resistors, capacitors, and ICs, are sourced based on the Bill of Materials (BOM).

PCB Fabrication: The PCB board is fabricated to meet the exact specifications outlined in the design. This includes layering, drilling, and etching.

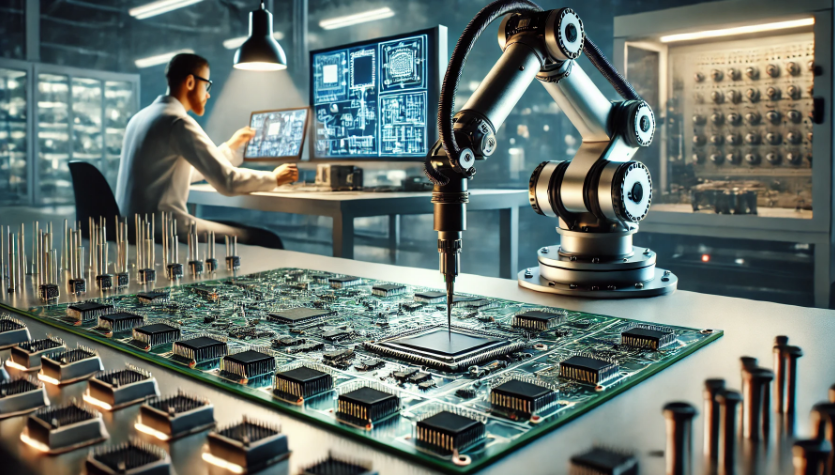

Component Placement: Components are placed on the PCB using automated machines or manually, depending on the complexity.

Soldering: Surface Mount Technology (SMT) or Through-Hole Technology (THT) methods are used to solder components onto the board.

Benefits of Prototype PCB Assembly

Error Detection: Early identification of design flaws saves time and reduces costs associated with rework.

Faster Time-to-Market: Rapid prototyping accelerates the development cycle, allowing businesses to launch products quickly.

Cost Efficiency: Testing a prototype avoids costly mistakes during large-scale production.

Improved Design: Feedback from prototype testing enables engineers to refine and optimize the design.

Customization: Prototyping allows for the evaluation of custom features before committing to mass production.

Choosing the Right Prototype PCB Assembly Service

Selecting the right service provider is vital for ensuring a seamless prototyping process. Here are some factors to consider:

Expertise and Experience: Look for a provider with a proven track record in PCB assembly across various industries.

Turnaround Time: Choose a service that offers quick turnaround times without compromising quality.

Quality Assurance: Ensure the provider follows strict quality control protocols and uses advanced testing methods.

Scalability: Opt for a service that can scale up from prototyping to full-scale production seamlessly.

Cost Transparency: A reliable provider should offer clear pricing with no hidden charges.

Conclusion

Prototype PCB assembly is an indispensable step in the electronics development process. It ensures that a product meets its design goals, performs reliably, and is ready for mass production. By partnering with the right PCB assembly service provider, businesses can streamline their development process, reduce costs, and deliver high-quality products to the market.

Write a comment ...